|

Stage 1 (2020)

"Development of new materials for sensor applications

and design and manufacture of work masks"

In

the first stage (2020), due to the very short working time (6 months), only

two activities were foreseen, namely:

1.1.

Obtaining sol-gel solutions and depositing the film on test substrates

1.2.

Modeling, design, and manufacture of masks

In

the first activity (1.1) four types of materials for nanosensors

were made, with different morphologies, for applications in CO2,

CH4, O3 and humidity (H2O-vapors)

detection. Several chemical synthesis pathways (sol-gel method and

hydrothermal method) were used to obtain metal films with different

structures. Thus, for each of the four compounds, different ways of

synthesizing of the different compounds were used:

a)

For CO2 target gas - two different synthesis pathways were used

to obtain CuO-ZnO type heterostructures.

b)

For the target gas O3 - hierarchical structures of ZnO-SnO2

type were prepared in two stages.

c) ZnO-NiO heterojunctions were

prepared for the CH4 target gas in two stages.

d)

For water vapor (H2O-vapor) two different materials were

prepared: ZnO nanowires and ZnO-NiO

nanowires, combining the sol-gel method with the hydrothermal one.

Each

sample was thermally treated differently, each treatment being performed

according to the specifics of the sample. The intermediate and final

parameters (temperature and duration) of the heat treatment were varied to

prepare sensitive materials, with different architectures that have a high

sensitivity, fast response, and short recovery times.

In

the second activity (1.2) the structure of sensors necessary for the

preliminary tests for the detection of greenhouse gases, as well as the

ceramic substrate were designed. The designed sensor consists of two

distinct types of structures:

-

one consisting of a zone of interdigitated metal

electrodes; nanostructured thin films have been deposited on their active

zone for the detection of greenhouse gases,

- the second consists of a Pt

resistor, which has the role of heating of the ceramic substrate.

The

arrangement of the interdigitated electrode was

done with the help of a dedicated design program (CleWin)

and was followed by obtaining the two work masks.

Mask

1 - Pt heater and

Mask

2 - Ti / Au transducers.

Stage 2 (2021)

"Characterization of new materials

and development of gas sensor"

Stage

2 contained the following activities:

2.1.

Modeling and design of gas sensors

2.2.

Manufacture of gas microsensor structures

2.3.

Characterization of microstructures by XRD, AFM, SEM, SE

2.4.

Optimizing the properties of the material and depositing films on

microchips

2.5.

Dissemination and participation in technical-scientific events

The

most important results obtained in the above activities were:

Activity 2.1. Preliminary electrical measurements

performed for the detection of gases of

interest

made on the layout designed in stage 1, demonstrated the need to modify the

metal paths

in the pad area. Thus, to obtain a more

precise electrical contact between the pads of the sensitive

structure

and the pins of the electrical connector used for measurement, the layout

of the final

structure

will have the pads of the interdigitated

structure doubled in width and the distance

between the

pads will be enlarged compared to the layout of the first stage of the

project.

Activity 2.2. After the work masks were processed, we

proceeded to the manufacturing stage of the transducers we want to use for

the detection of target gases. They were made of 4” ceramic wafers. A

number of 3 ceramic wafers with a thickness of 100 µm were processed, the

total number of translators obtained being 150 chips.

Activity 2.3. In this second stage, a number of 9 new

types of films for the detection of greenhouse gases (CH4, CO2, O3, H2O-vapors) were

obtained, which were structurally (XRD) and morphologically (AFM, SEM)

characterized. These films were deposited by chemical methods (sol-gel

method, hydrothermal synthesis or liquid exfoliation), the chosen method

taking into account the configuration, respectively the dimensions of the

translators used).

Activity 2.4 Optimization of the film properties was

done by:

a)

Variation of the type of films: mixed or doped with different metals (Sn, In, Cu, Pd), choosing the

appropriate dopant for the target gas.

b)

The use of three types of translators of different sizes and thicknesses,

namely:

large

Au (IDE) / thin alumina transducer,

small

Au (IDE) / thin alumina transducer,

small Au (IDE) / thick alumina transducer.

c)

the choice of different deposit methods

d)

variation of the synthesis parameters: precursors, solution concentrations,

synthesis times, different number of deposited layers

According

to the AFM and SEM characterization techniques, the films deposited on

large transducers of type Au (IDE) / thin alumina show a higher degree of

uniformity compared to those deposited on small transducers of type Au (IDE)

/ thin alumina or alumina thick.

Doping

with different metals, combined with the deposition method, has a double

role, having an influence both on the morphology (following the

hydrothermal synthesis, rods/tubes can be obtained) and on the sample conduction.

The

materials developed and characterized in stage 2 of this project will be

tested in the stage 3, to be used as microsensors for the detection of greenhouse gases, by

connecting to an electronic module.

Activity 2.5. During this year's dissemination, a

paper was sent to an ISI journal (Nanomaterials)

and an oral communication was given at the Conference of Scientific

Research of the Romanian Academy.

Stage 3 (2022)

"Sensor testing, characterization and

technology demonstration"

The 3rd stage had the following

activities:

3.1. Testing and characterization of sensors for

each model obtained

3.2. Demonstration of the experimental model. Verification/Examination of the

reproducibility and reliability of the sensors and demonstration of the

experimental model

3.3. Dissemination and participation in

technical-scientific events

Activity 3.1. This year, in order to

optimize the experiments, the following were carried out:

-

a

new sensor-cell

-

a

new type of transducer (PIII)

-

for the ozone detection the experimental setup was modified by adding

new components, the technological level being included at TRL4.

-

a series of novel sensitive films based on CuO

and CoO with significantly improved properties

compared to the previous films obtained in the second stage were deposited

by sol-gel method, both on the PI and PIII type transducers.

The

structural characterization of the films was carried out by XRD, while the

morphological characterization was achieved by AFM and SEM and the sensing

measurements were performed separately for each gas. The greenhouse gases

were detected at working temperatures in the 25-2200C range, these low

temperatures being considered an advantage from the

economic point of view.

Activity 3.2.

The

reliability and reproducibility of each sensor for the investigated gas

were tested for 6 months. In order to assess the basis of the electrical

resistance, the sensor was maintained in the carrier gas (10 minutes),

followed by the injection (10 minutes) of the target gas with a fixed

concentration, all these steps providing the reproducibility measurements.

The sensor recovery process involves subsequently injections (for 3 times)

of the target gas, keeping the sensor in the carrier gas after each

injection (10 minutes).

The demonstration of the

experimental model was successfully carried out using the new sensor-cell.

The portable system was developed for the data acquisition from real-time measurements

with the help of a phone/ mobile application through a bluetooth

connection.

Activity

3.3.

Dissemination:

-

The paper “Investigation of the effects of rapid

thermal annealing on the electron transport mechanism in nitrogen-doped ZnO

thin films grown by RF magnetron sputtering”, authors: Simeon Simeonov, Anna Szekeres, Dencho Spassov, Mihai Anastasescu,

Ioana Stanculescu, Madalina Nicolescu, Elias Aperathitis, Mircea Modreanu,

Mariuca Gartner sent last year to Nanomaterials was published

online: 2022, 12 (1), 19; https://doi.org/10.3390/nano12010019

- The paper “Evolution of

physical properties during nanocrystalline graphene film formation”, authors: Mariuca

Gartner, Mihai Anastasescu, Hermine Stroescu, Jose Maria Calderon-Moreno,

Silviu Preda, Octavian-Gabriel Simionescu, Andrei Avram, Octavian Buiu, Coatings, is under revision.

- The paper “Influence

of Zn-doping on the properties of ITO sol-gel films deposited on different

substrates for CO2 sensing”, Madalina

Nicolescu, Maria Covei, Mihai Anastasescu, Silviu Preda, Irina Atkinson,

Hermine Stroescu, Luminita Predoana, Maria Zaharescu, Mariuca Gartner, Nanomaterials is under evaluation.

- The oral communication“MOX resistive

microsensors for low concentration methane detection”, authors: Paul

Chesler, Cristian Hornoiu, Mariuca Gartner, Marin Gheorghe will be held in November 2022, at the 9th International Electronic Conference on Sensors and

Applications, Section: Chemo-

and Biosensors (ECSA-9),

1-15.11.2022, as a result of the abstract’s acceptance.

Final

conclusions of the project

The

TRL 4 level, specified in the project proposal, was achieved by obtaining

sensitive materials deposited on micro-chips (transducers) and also by

testing them in laboratory conditions.

We

consider that this project has successfully accomplished all the proposed objectives,

leading to the obtaining and optimization of the monitoring greenhouse

gases system, related to human activities, without reducing the economic

activities. None of these results would have been possible without the funding

received from UEFISCDI.

Note

The project aimed to monitor greenhouse gases that are directly related to human activities: CO2, CH4, O3, humidity. The main result of the project was the obtaining of new technologies for manufacturing a network of miniaturized gas sensors.

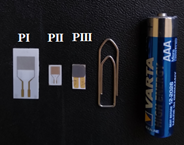

For this purpose, three transducer prototypes (Fig. 1 - PI, PII and PIII) with porous alumina support and interdigitated electrodes of noble metals (Au or Pt) were manufactured, in order to achieve a good charge transfer at the gas-solid interface (targeted gas - sensitive film). Sensitive films of different chemical composition, In2O3, ZnO/NiO, CuO, CoO, were prepared by eco-friendly, cost effective chemical wet methods (hydrothermal, sol-gel) from commercially available reagents. The sensors obtained from the sensitive films deposited on the transducers were tested in the target gases using the setup schematically shown in Fig. 2. The test sensor cell, originally made of quartz, was mechanically improved, resulting a cell of aluminum, which will be patented.

A portable system was developed for real time data acquisition, with subsequent data transmission via Bluetooth connection to a mobile phone (Fig. 3). Taking into account all , a substantial contribution was achieved for informing, predicting and stimulating actions for the greenhouse gases monitoring.

|

|

Fig. 1 Transducer prototypes (alumina substrate with Au or Pt IDE) |

Fig. 2 Schematic representation of the experimental setup used for sensoristic measurements |

|

Fig. 3 Portable system for real-time data acquisition |

Web site and all contents © Copyright YourName 2005, All rights reserved.

Free

website templates

|